Product Introduction: Automatic Top Labelling Machine

Shanghai Guangzhi Automation Co., Ltd. designs cutting-edge Automatic Top Labelling Machines to revolutionize labeling efficiency across global production lines. Our machines integrate precision engineering, intelligent controls, and robust durability, ensuring seamless operation in high-volume environments while reducing downtime by 40% and label waste by 25% .

Core Features & Technological Advantages

Ultra-Precision Labeling

±1mm Accuracy: Utilizes high-resolution sensors and servo-driven mechanisms to eliminate wrinkles, bubbles, or misalignment on curved surfaces (e.g., round bottles, conical containers).

Photoelectric Tracking: Auto-detects product presence and self-corrects label positioning, reducing material waste by 15%.

High-Speed Flexibility

20–200 Containers/Minute: Adjustable speed via touchscreen HMI supports rapid transitions between product sizes (?20–150mm) and label dimensions (width: 15–200mm; length: ≥20mm).

Multi-Format Compatibility: Handles round, square, and tapered containers with optional 360° Wrap-Rolling or Front-Back Dual-Labeling modules.

Smart Automation

PLC + Touchscreen Control: Siemens PLC and 10-inch HMI with multi-language interface enable real-time fault diagnostics and automated error recovery.

Energy-Saving Mode: Reduces power consumption by 30% during idle periods.

Industrial Durability

Stainless Steel 304 Frame: Compliant with GMP, FDA, and ISO standards for hygiene-critical industries.

Safety Interlocks: Emergency stops and overload protection ensure operator safety.

Line Integration

Technical Specifications

| Parameter | Specification |

|---|

| Labeling Speed | 20–200 containers/minute |

| Labeling Accuracy | ±1mm |

| Applicable Product Diameter | ?20–150mm |

| Label Dimensions (W × L) | 15–200mm × ≥20mm |

| Power Supply | 220V, 50/60Hz |

| Control System | PLC + Touchscreen HMI |

Industry Applications

Food & Beverage: PET bottles for water, jars for sauces, and cans for dairy products.

Pharmaceutical: Vials, ointment tubes, and sterile packaging under cleanroom conditions .

Cosmetics & Chemicals: Waterproof labels on HDPE/LDPE containers for shampoos and detergents.

Industry-Specific Solutions and Case Studies

1. Food & Beverage: Streamlining Sauce Jar Labeling

Challenge: A Chinese sauce producer faced ±3mm label misalignment on curved jars, causing 8% waste .

Solution: Shanghai Guangzhi’s 360° Wrap-Rolling Module with photoelectric tracking ensured ±1mm accuracy, reducing waste to 0.5% and increasing line speed by 35%.

ROI: Full ROI achieved in 10 months via reduced material costs and labor savings.

2. Pharmaceutical: Compliance-Driven Vial Labeling

Challenge: A vaccine manufacturer required sterile, error-free labeling for traceability under FDA guidelines .

Solution: Integrated RFID Tagging Module and stainless steel construction met GMP standards. Real-time data sync with ERP systems ensured 100% compliance.

Outcome: Zero recall incidents in 18 months; 99.9% labeling accuracy audited.

3. Cosmetics & Personal Care: Luxury Brand Packaging

Challenge: A French skincare brand needed wrinkle-free labels on conical bottles for premium aesthetics.

Solution: Servo-Driven Curved Surface Adaption technology adjusted label tension dynamically, achieving bubble-free adhesion on complex geometries.

Result: 98% client satisfaction in retail audits; production flexibility for 10+ bottle designs.

4. Logistics & Warehousing: Pallet Labeling for E-Commerce

Challenge: An e-commerce warehouse struggled with SSCC code errors during peak seasons .

Solution: Front-Back Dual-Labeling mode applied pallet tags in 2 seconds/unit, integrated with WMS via Ethernet/IP.

Efficiency Gain: 200 pallets/hour labeled; 99.5% scan success rate.

Service & Support

Global Technical Assistance: On-site installation, operator training, and 24/7 remote diagnostics .

Spare Parts Guarantee: Critical components (sensors, motors) dispatched within 24 hours globally.

Customization: Tailored solutions for high-temperature labels, RFID integration, or niche containers .

APPLICABLE BARREL TYPE

COMPANY PROFILE

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

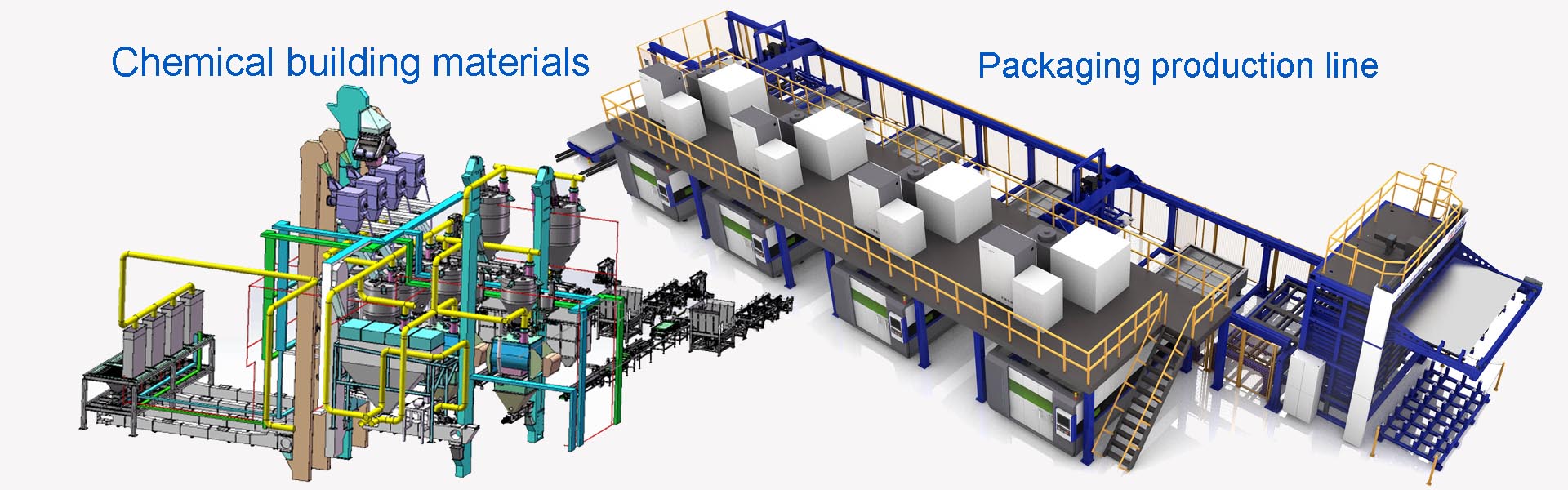

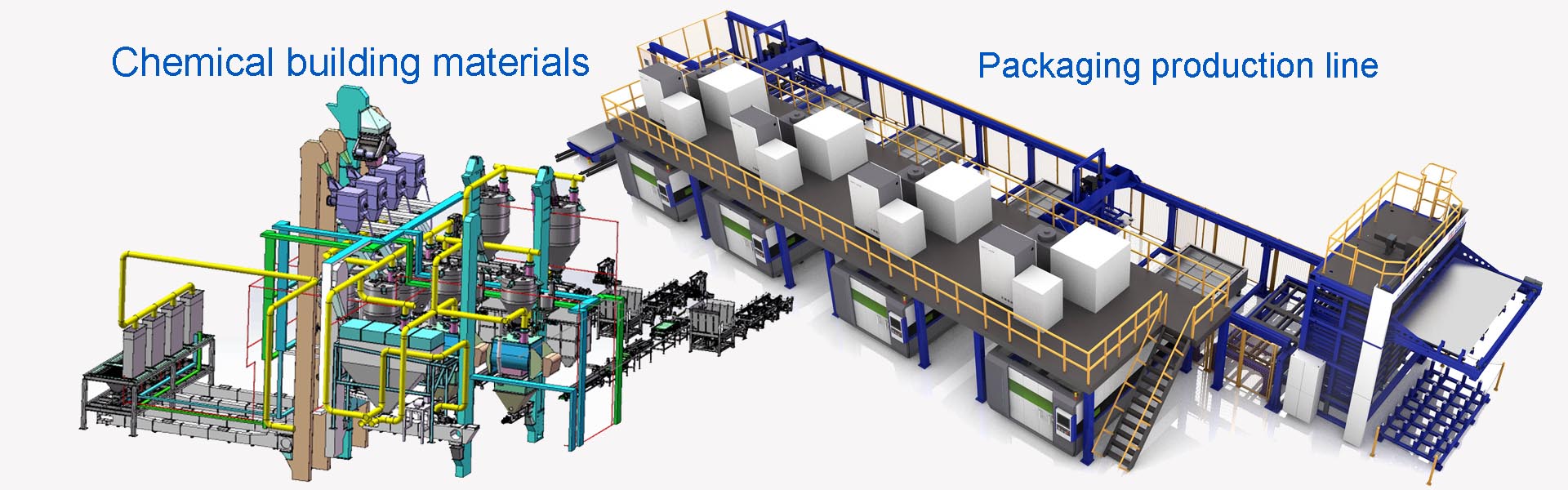

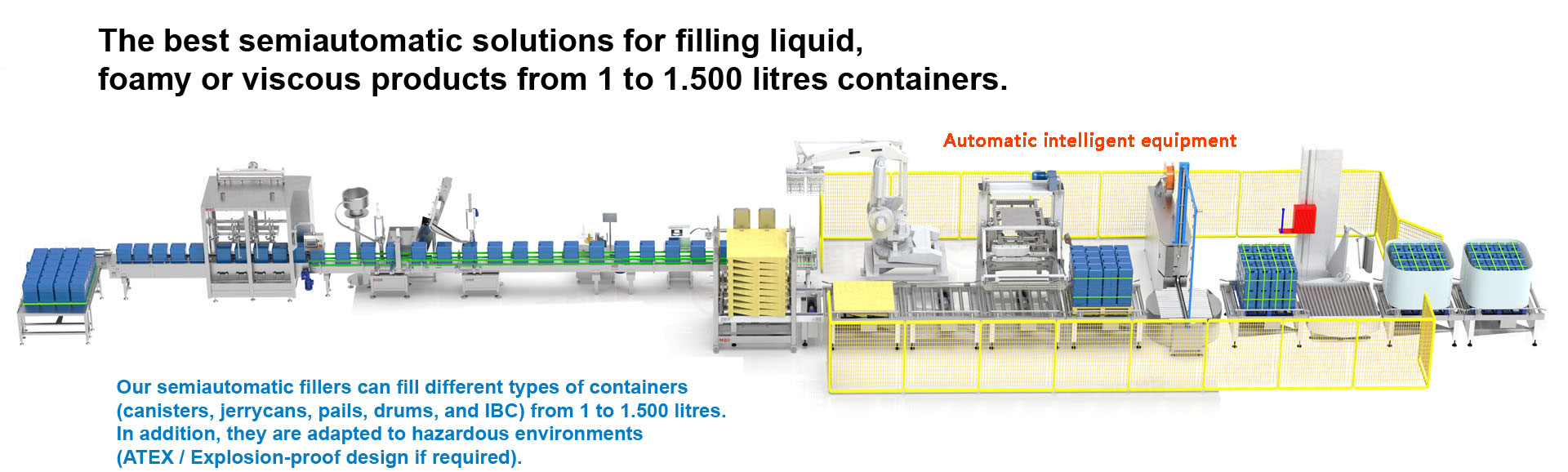

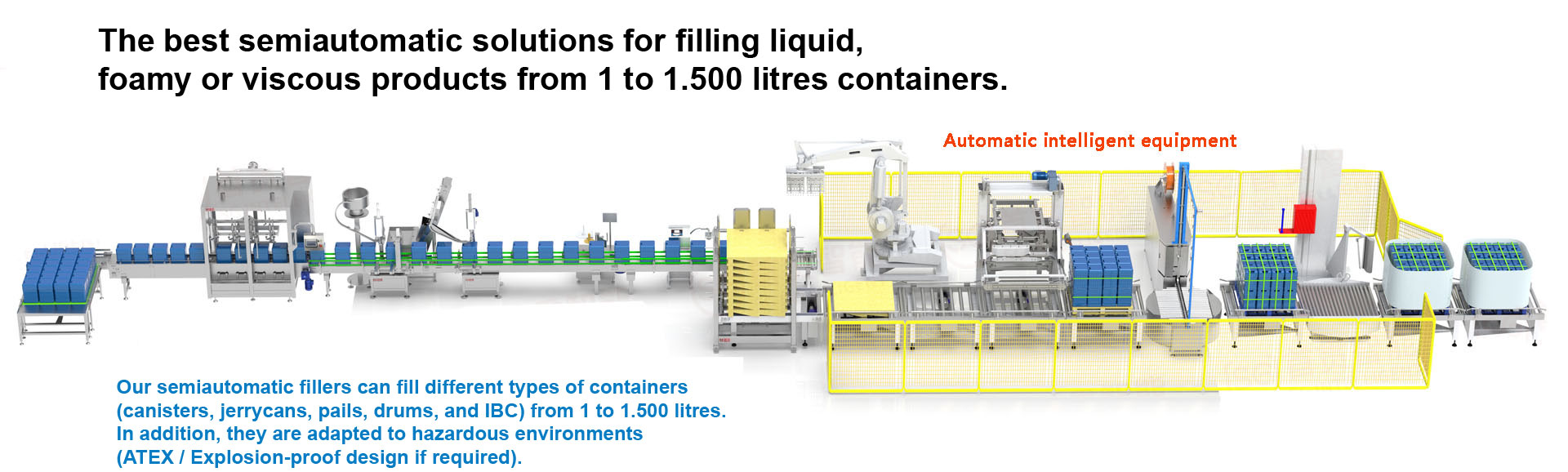

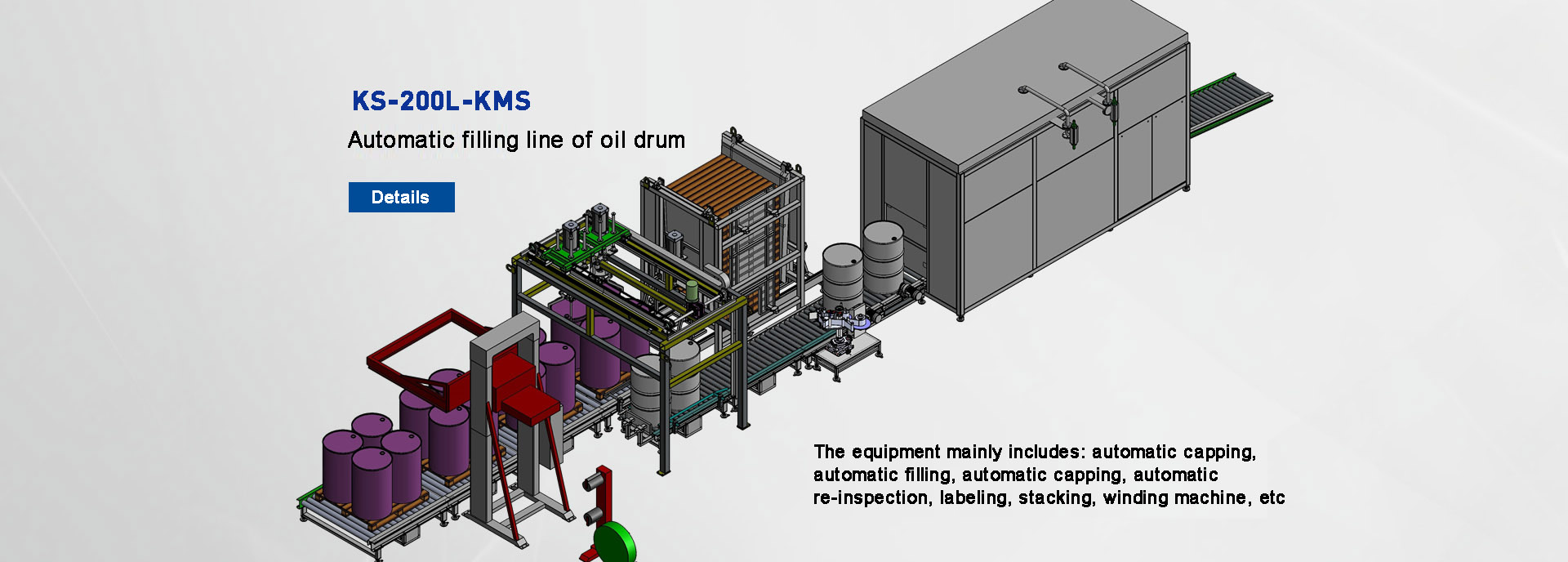

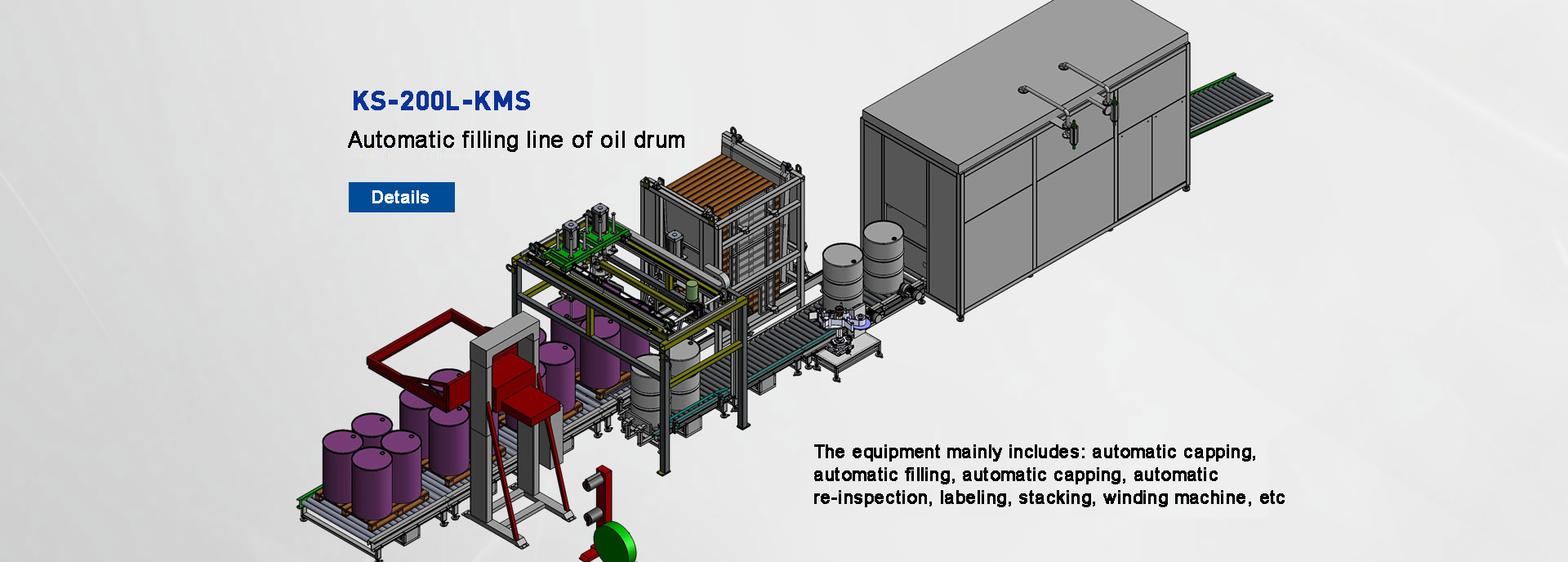

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Company Certificate

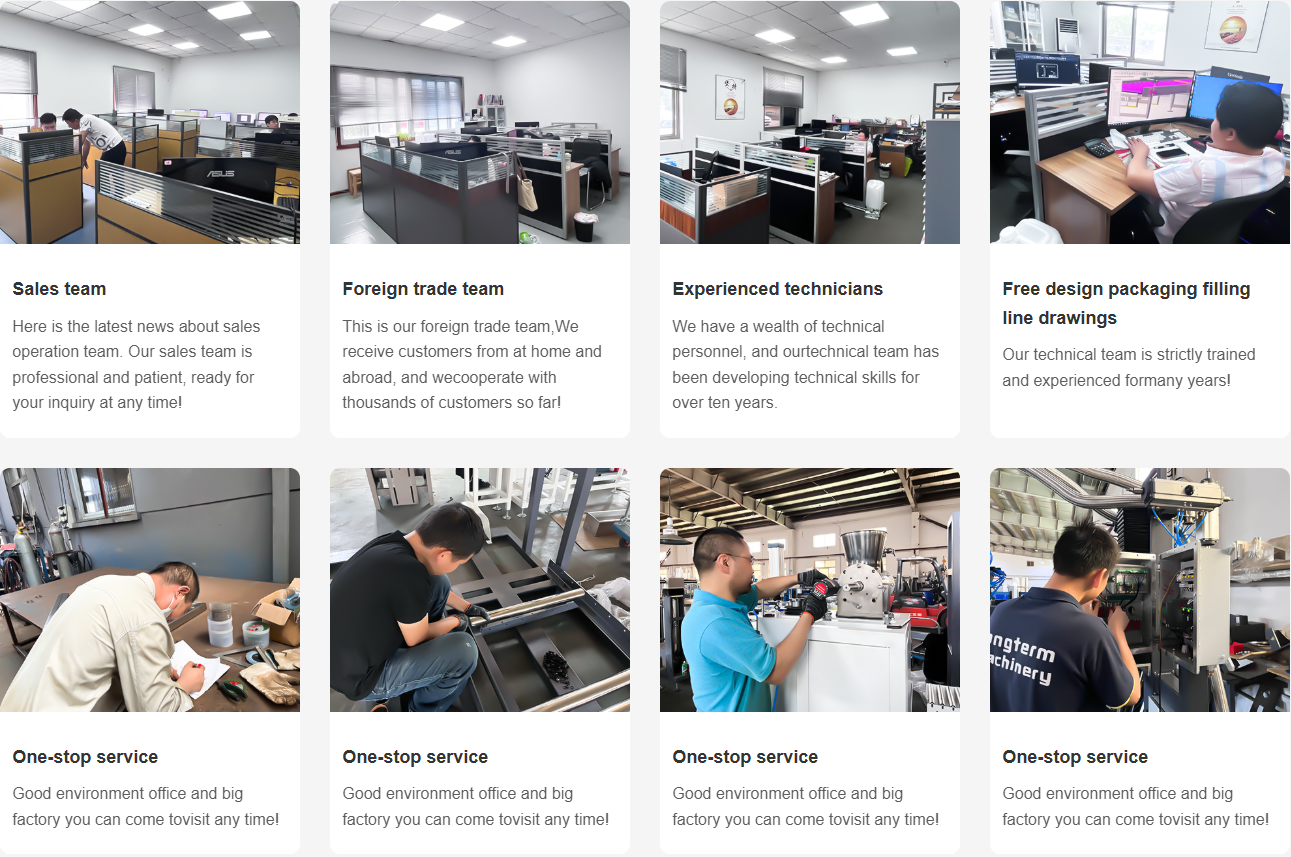

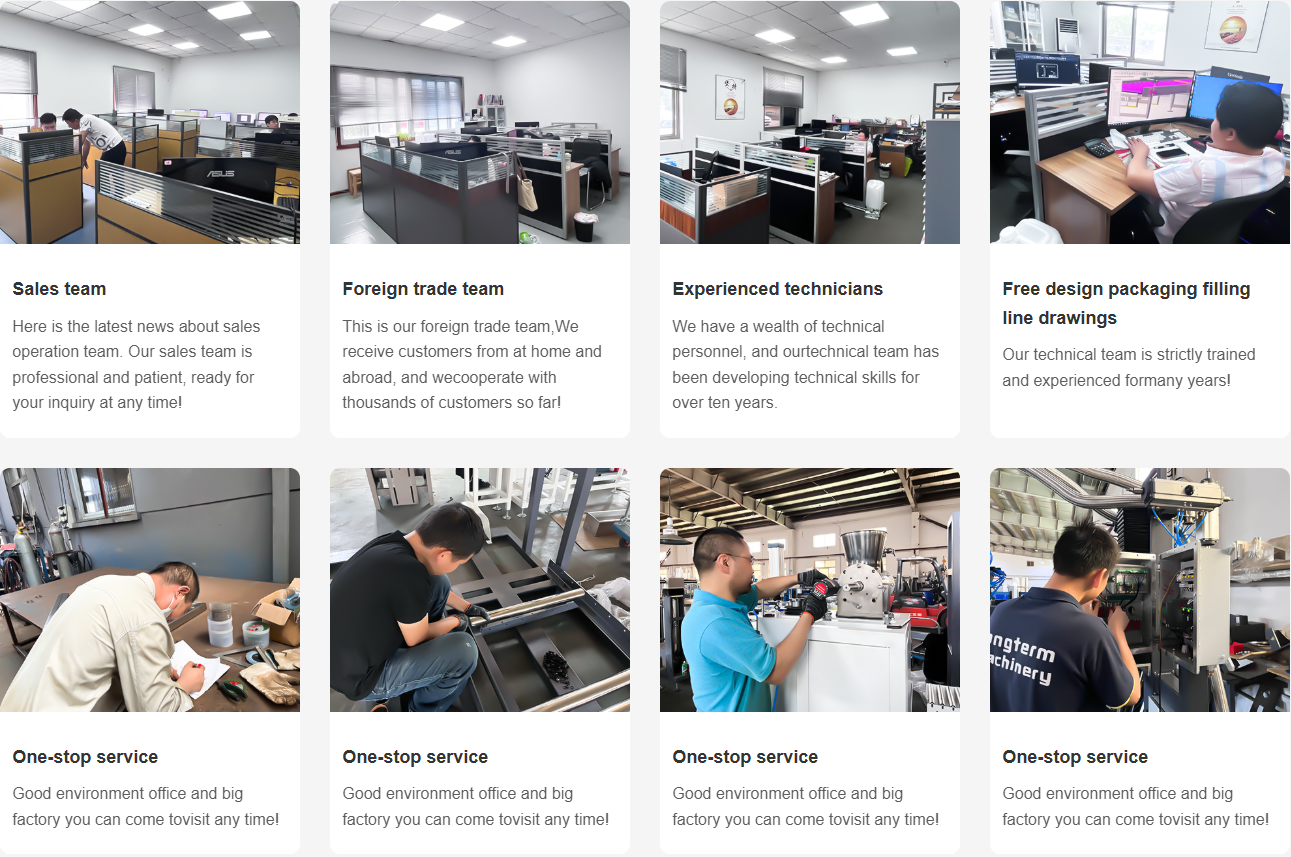

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance

This is a partial

service for us

in China.

Over 30 years of experience, every time we produce in

Shanghai, our friends can visit our factory at any time.

Brand components

We will ensure that our company's equipment has safety, stability, high efficiency and intelli-gent technology, so as to meet your needs, we can also cooperate with you in selecting in-ternational product brand production and business.

Our service

Complete solution provided

Telephone exchange joint business design plan, you can also visit our company ; we have a good environmental office vehicle,you can visit from time to time.

Duty after death

Our music team has a strong heart, and the customer's suspicions are also the purpose 24 hours of phone cell service and listing to the conversation at any time.

Technology group

We have a wealth of technical personnel and our technical team has been developing technical skills for over ten years.

Successful collaboration

Our factory in Shanghai. China provides free training for our technical staff.Better guarantee good product safety , our company provides safety, convenience, high efficlency packaging servic.

packge and delivery

Multiple Transportation way :Express(Fedex/DHL/TNT/EMS/UPS etc),air and shipping for your choose

Our in-house designers and engineers have produced countless great designs for customers from different industries

1

Can we get your free samples?

Samples can be offered for free. But courier cost for the samples should be at buyer's account.

2

Can you print our LOGO in flatware set?

Yes.we can print the logo on the flatware set as your requirements.Embossed, laser,stamped and engraved are available.

3

How long is the delivery time of sample?

Samples from stock can be sent within 1-3 days. New produced samples will be sent within 5-15 days.

4

Is there any MOQ for what I purchase?

Yes, we have MOQ for mass production. Different item with different package has different MOQ. Please contact us for more details.

5

Do you accept OEM or ODM services?

OEM and ODM are accepted!

6

What is 18-10 Stainless Steel Flatware?

18-10 refers to the composition of stainless steel. It contains 18% chromium and 10% nickel for excellent strength and corrosion resistance.

CONTACT US

Skype: fayfaywang1027

QQ: 429682794

Whatsapp: 008618016442021

E-mail: glzoncn@163.com

https://glzon.en.alibaba.com/

cel: +0086 18016442021